Home / All / GPB Design & Customization FAQ / What's the process of 3D printing Mock-up for custom perfume bottle?

What's the process of 3D printing Mock-up for custom perfume bottle?

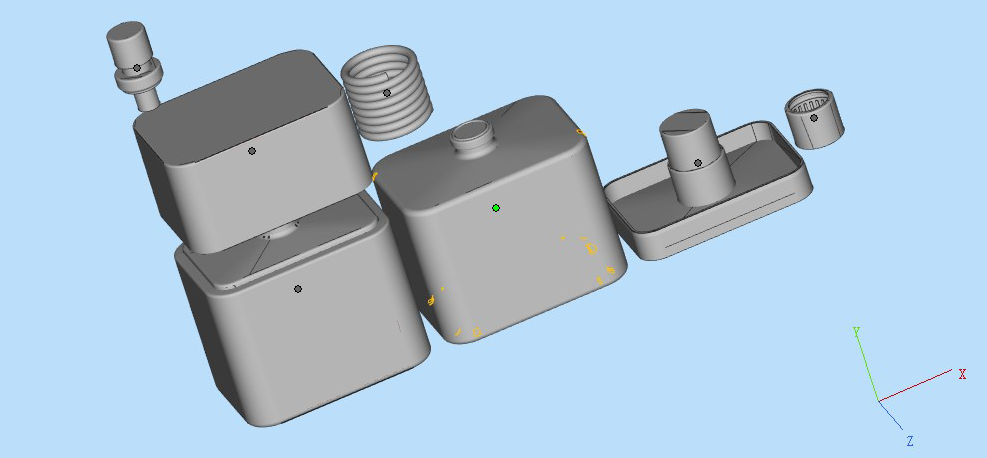

Step 1. 3D Drawing build

At GPBottles, we have professional designers who can create accurate 3D drawings based on the ideas or specifications provided by the buyer. The file formats we work with include STEP, STL, and OBJ, which are compatible with 3D printers for producing mock-ups. Typically, all accessories are designed together in a single file to ensure seamless integration for each component of a perfume packaging design. Additionally, we also create 2D drawings and renderings as part of our services.

Step 2. Material selection

Import Resin

Pure white, used to print precise, good toughness, good strength part.

Photosensitive Resin

With smooth surface and details of photosensitive resin, the printed parts is colorness, it looks like the real transparent plastic.

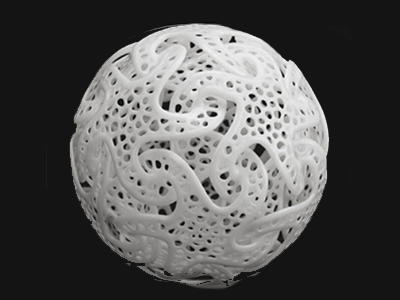

Nylon

It's used to print eletronics, power tool with advantage of anti high temperture, toughness and strength.

Flexible Glue

Anti hot and cold, it has good elasticity, good strenght, and tear resistance

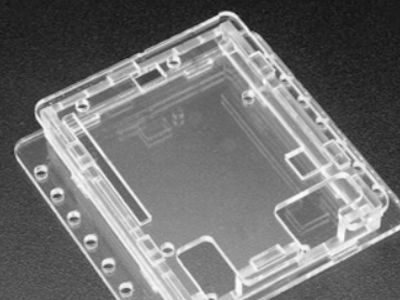

PC

Anti high temperature, good photopermeability, high transparency, light weight, good overall performance.

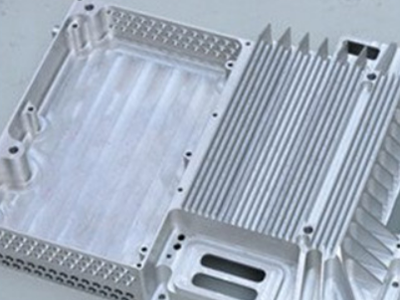

Aluminium alloy

Good designability without limit of constructure, low density, good specific strength

Zinc alloy

Kinds of surface treatment, good corrosion resistance, suitable for complicate shape and thin wall parts.

ABS

Cheap cost, good strength, kinds of color avaiable

Step 3. Surface treatment

CNN processing

Color painting

Oxidization & Carbonization

Silk screen printing

Electroplating

Laser emboss

Water transfer printing

Based on kinds of surface treatment, we can provide mock-up of perfume packaging as the full set design of final effect. That will be easy for product department to present best visual effect to marketing department to have better sales evaluation.

Are you looking for a reliable manufacturer of unique perfume bottles?

500+ Ready stock perfume bottle designs & customization service support your start-up business.Contact Person

- Name:

- Ben Li

- Tel:

+86-18057174708

- Email:

- ben@gpbottles.com

- WhatsApp:

- 8618057174708

- Address:

- Head Office: Room 2321, Building 5, No.99, Wangzhou Rd, Hangzhou, China