3D Printing technology support perfume packaging design

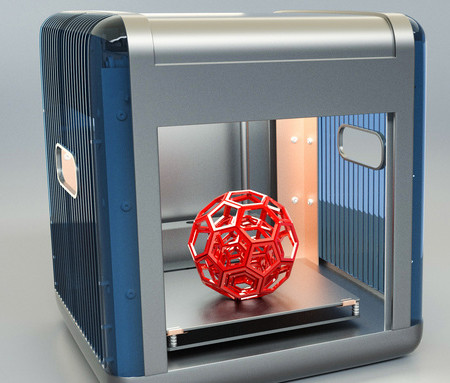

3D Printing: Revolutionizing Prototyping in Perfume Packaging Design

Emerging in the mid-1990s, 3D printing, also known as additive manufacturing, represents a paradigm shift in how objects are created. While its foundational principle—building a final product layer by layer from a digital blueprint—bears a conceptual resemblance to the linear process of ordinary printing on paper, the technology itself is profoundly more complex and versatile. It utilizes advanced techniques such as stereolithography (SLA, or light curing) and selective laser sintering (SLS), among other rapid prototyping technologies. Instead of ink, a 3D printer is fed with specific printable materials—including liquid resins, fine powders (like nylon or metal), or specialized filaments. Under precise computer control, these materials are solidified, fused, or laminated in successive ultra-thin layers, meticulously translating a three-dimensional digital drawing into a tangible, physical object with remarkable accuracy.

This innovative process is exceptionally well-suited for small-scale, high-value manufacturing, particularly for producing highly customized and intricate items. Its impact is vividly seen in the creation of functional prototypes and testing mock-ups for perfume packaging, where aesthetics, ergonomics, and functionality must be evaluated long before mass production commences.

At GP Bottles, we harness the power of this technology to bring your packaging concepts to life with speed and precision. To provide the most realistic representation, we select materials that best simulate the final product's properties. For instance, we use high-transparency acrylic to create mock-ups for glass bottles, achieving excellent clarity and weight approximation. For perfume caps, PP (polypropylene) material is employed to test form, fit, and snap mechanisms. For designs intended for zamac or aluminium caps, we can even produce mock-ups using aluminium material itself, allowing for authentic assessment of heft, metallic finish, and detailed engraving.

Integrating 3D printing into our development workflow offers immense strategic advantages. It significantly mitigates risk by allowing for thorough design validation, user testing, and market feedback on a physical model before investing in expensive production molds. This proactive approach saves substantial time by condensing weeks of traditional prototyping into days and reduces overall costs by identifying and correcting potential design flaws at the earliest possible stage. Ultimately, this technology empowers our clients to innovate with greater confidence, ensuring that the final manufactured packaging is not only beautiful but also perfectly engineered.

Are you looking for a reliable manufacturer of unique perfume bottles?

500+ Ready stock perfume bottle designs & customization service support your start-up business.Contact Person

- Name:

- Ben Li

- Tel:

+86-18057174708

- Email:

- ben@gpbottles.com

- WhatsApp:

- 8618057174708

- Address:

- Head Office: Room 2321, Building 5, No.99, Wangzhou Rd, Hangzhou, China